We are passing through a very challenging time due to the consequences of the coronavirus. And we recognize that providing people ...

Read moreProduct Protection Creator

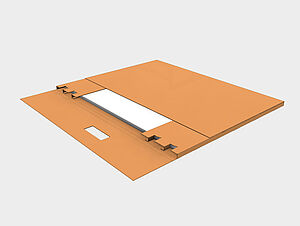

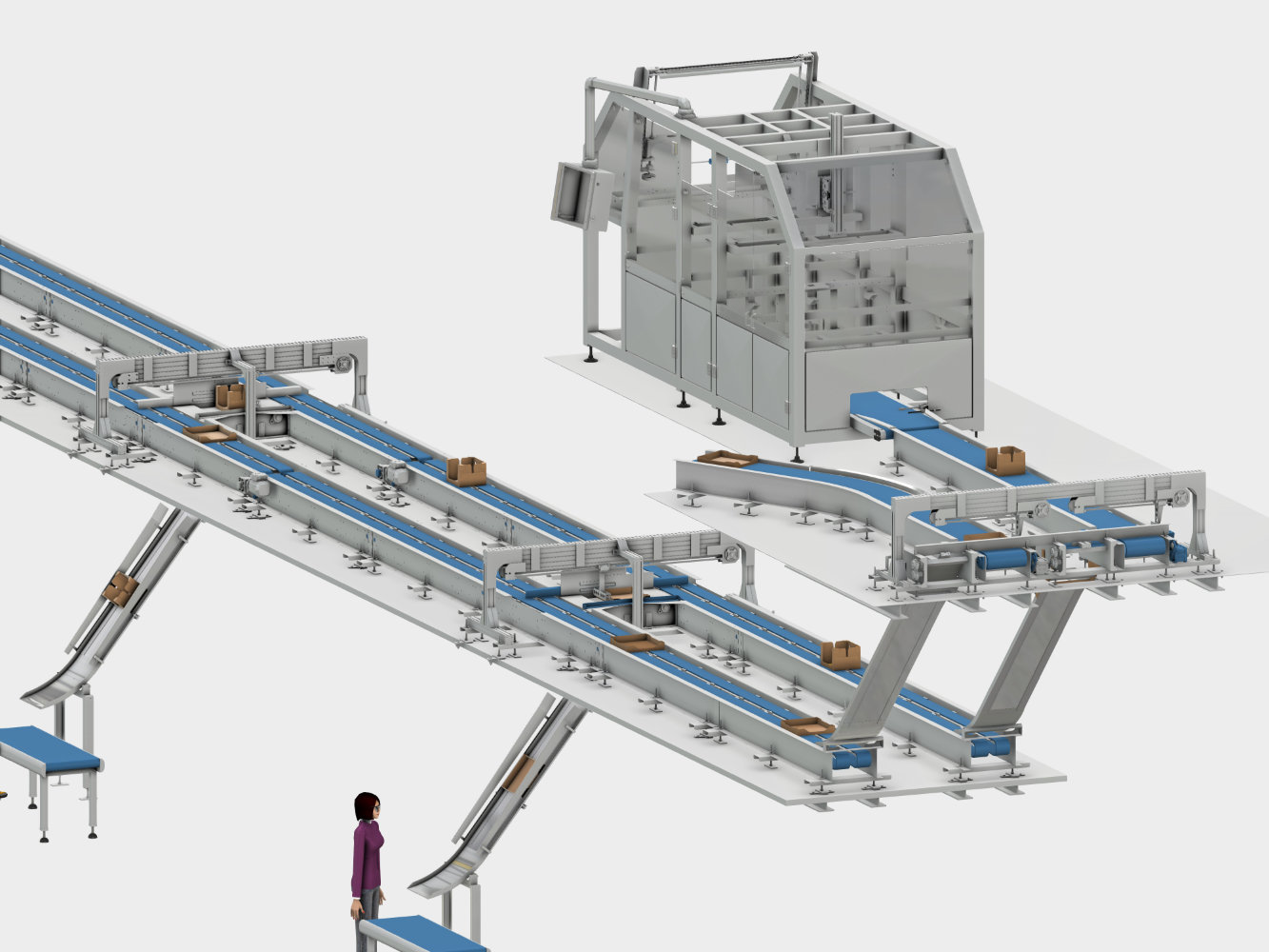

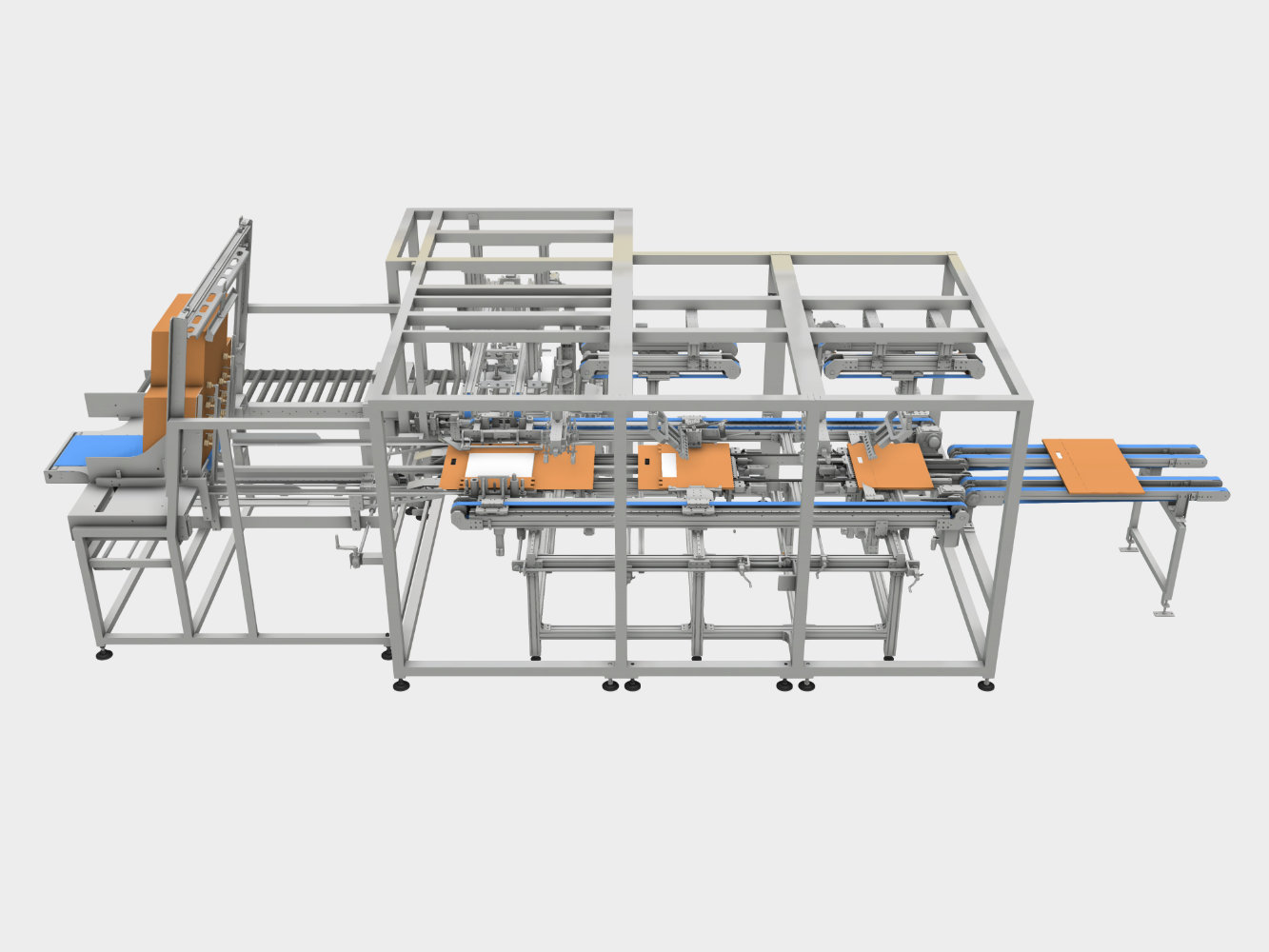

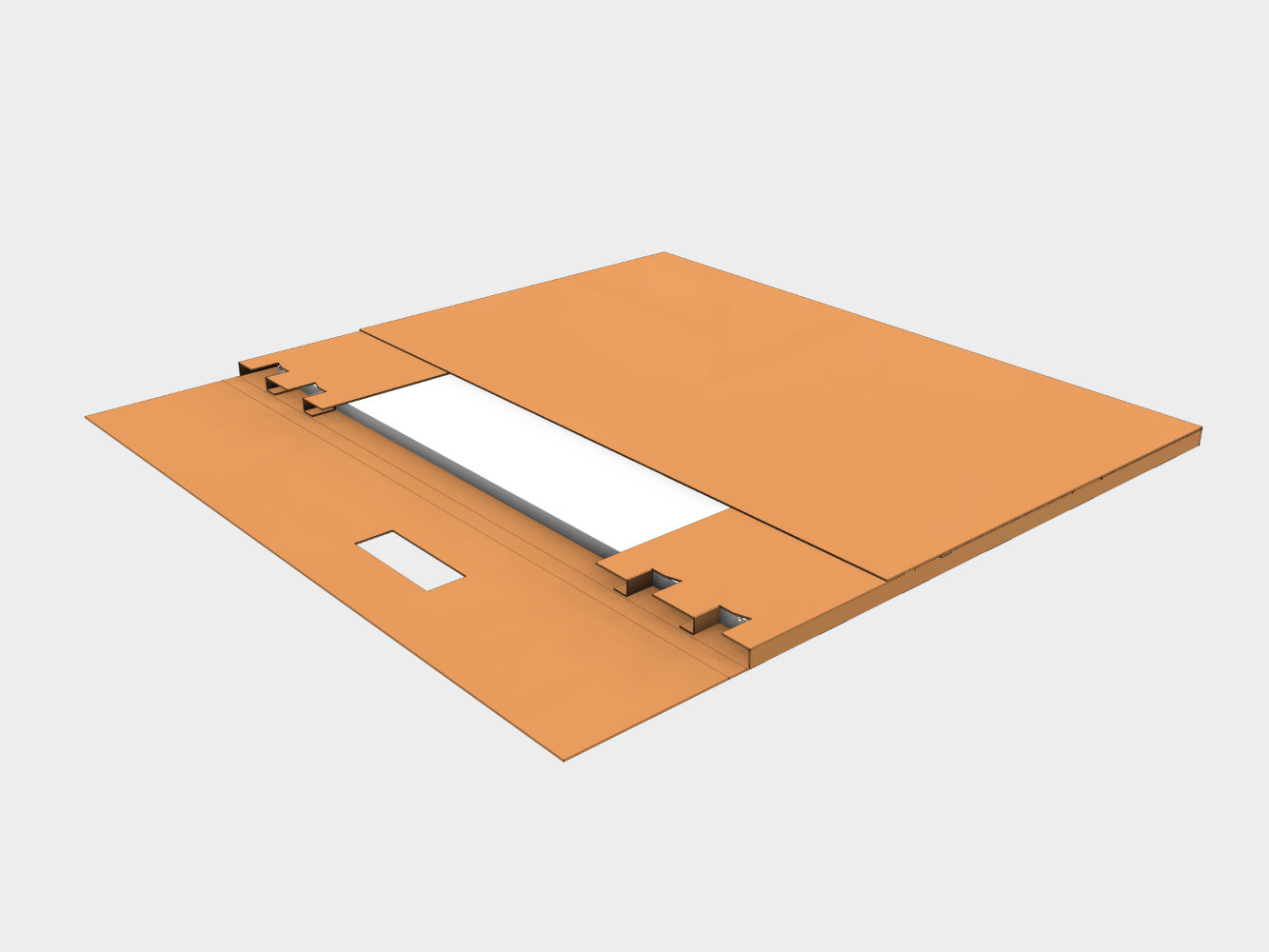

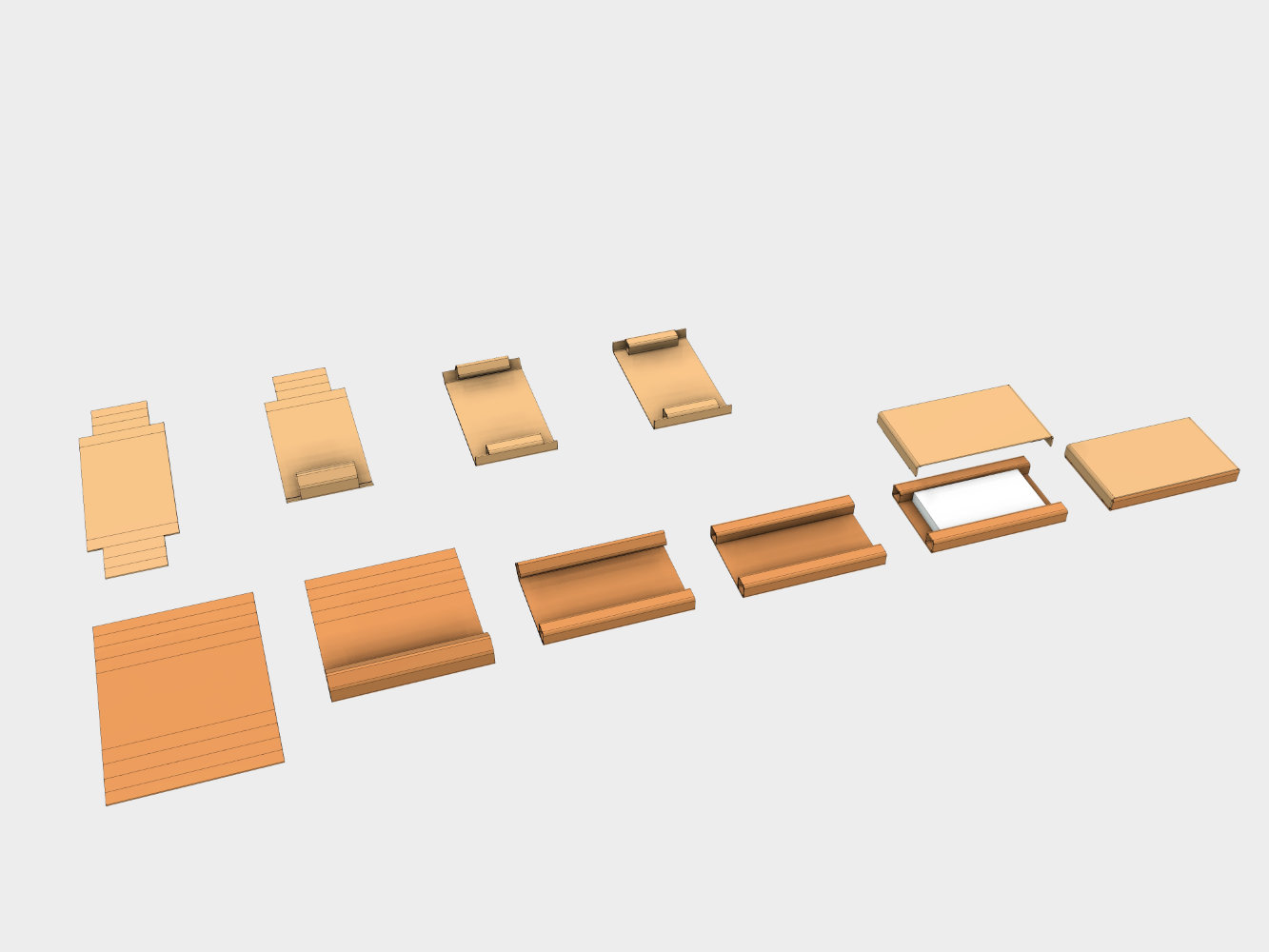

The prefabricated carton blank is folded around the product and glued with hot glue. The packaging of the product can be executed complete and gapless as well as with windows. The one-piece flat corrugated board blank, provides a 4-sided edge protection, which is integrated in the form of push-in flaps in the blank and is erected by the machine. High flexibility for format sizes, supported by intuitive and fast changeover, characterizes the system. Integration into a high-performance packaging line, consisting of: a feed system, a packaging system and palletizing is possible at any time.

Your Advantages

- Performance up to 15 Kartons/min.

- Prefabricated carton blanks, 1-part

- Elimination of plastic packaging and other packaging materials

- Optimization of logistics costs

- Optimal for products such as:

- Drawers

- Corpus

- Fronts

- Flat formats

- Filling of product into cardboards is gentle through Pick & Place systems

- Interfaces to your process control system and remote maintenance

| Length | 420 - 1200 |

| Width | 360 - 800 |

| Hight | 5 - 25 |

Metrics in mm

Product Protection Creator

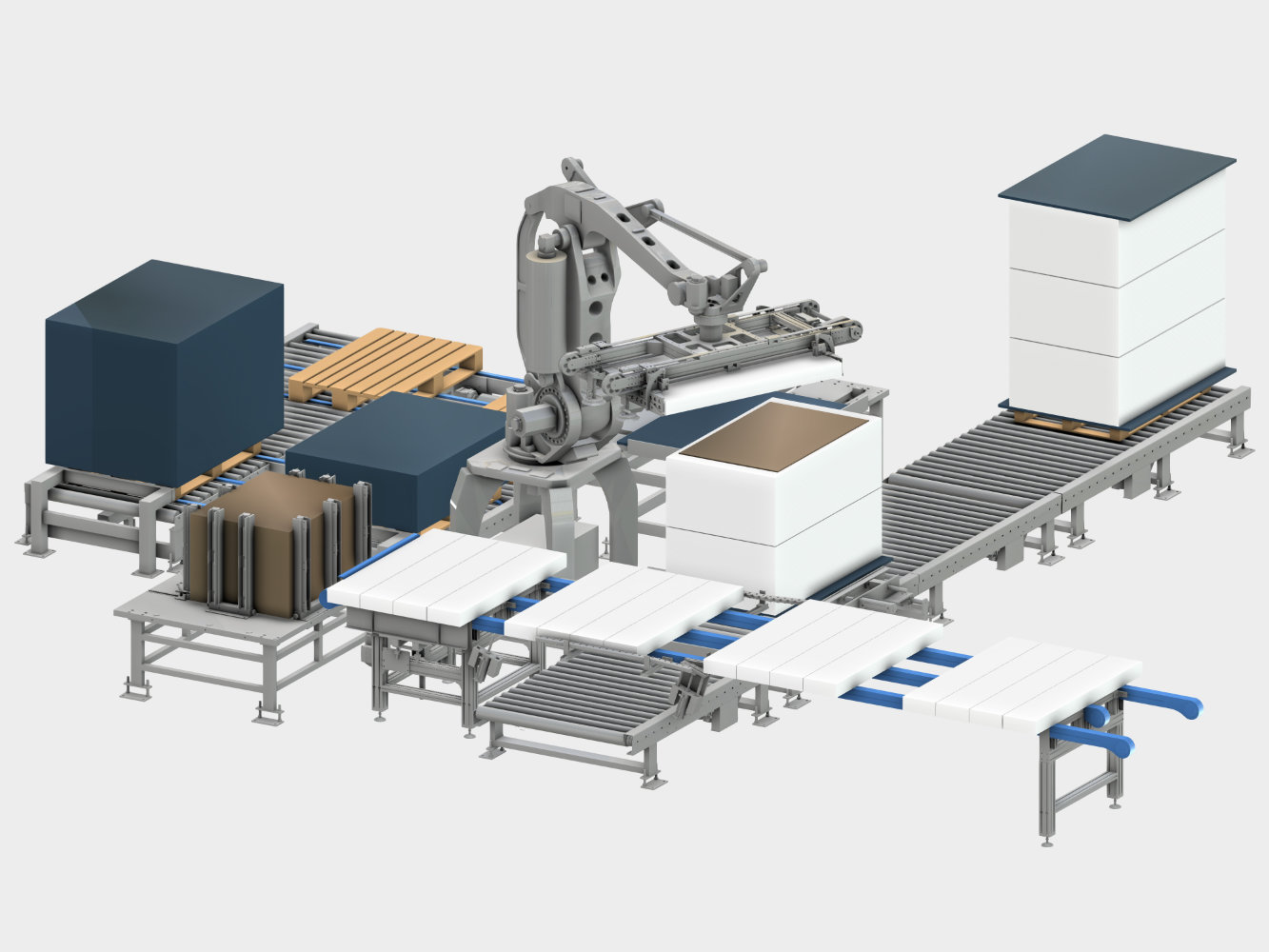

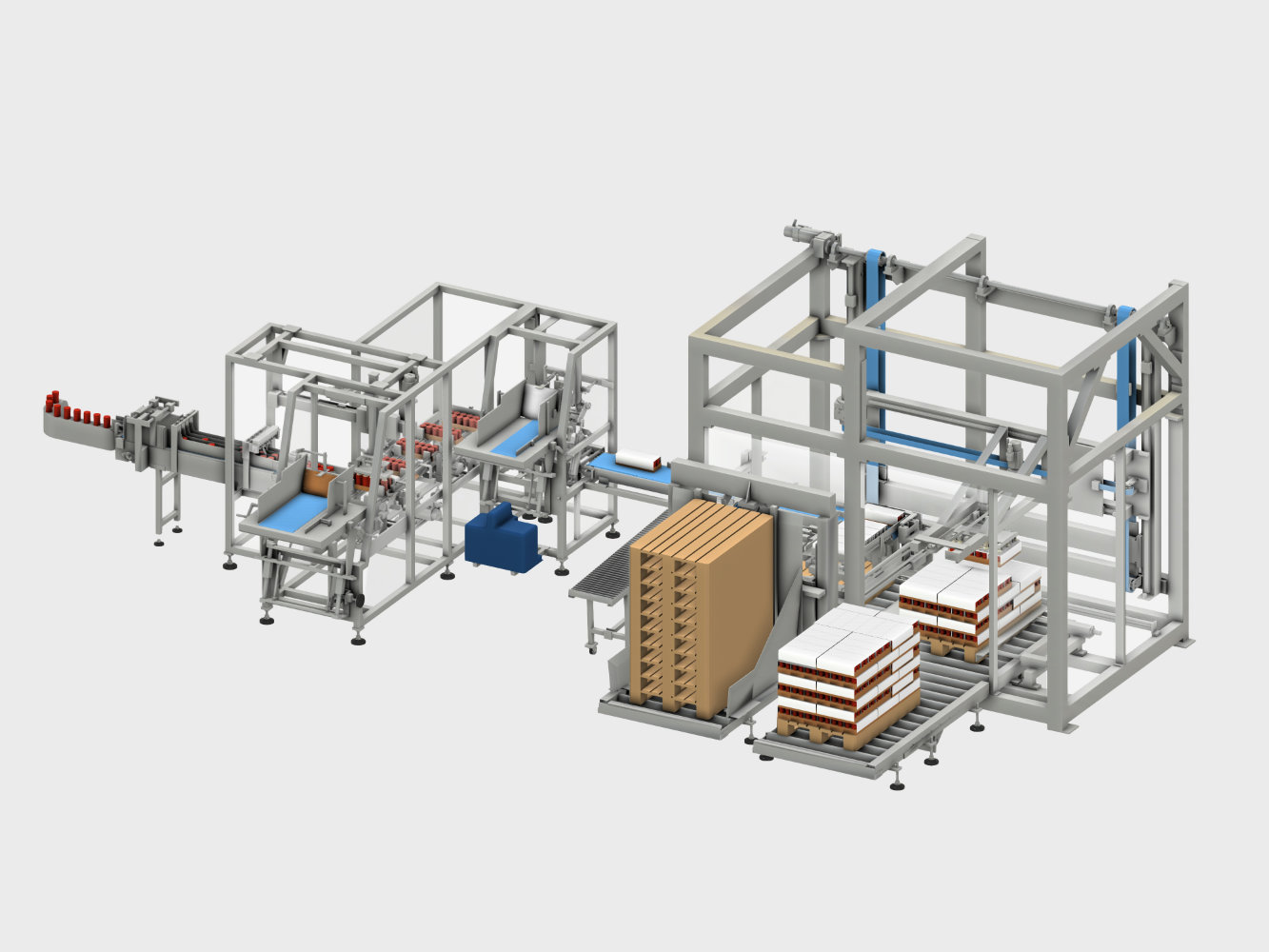

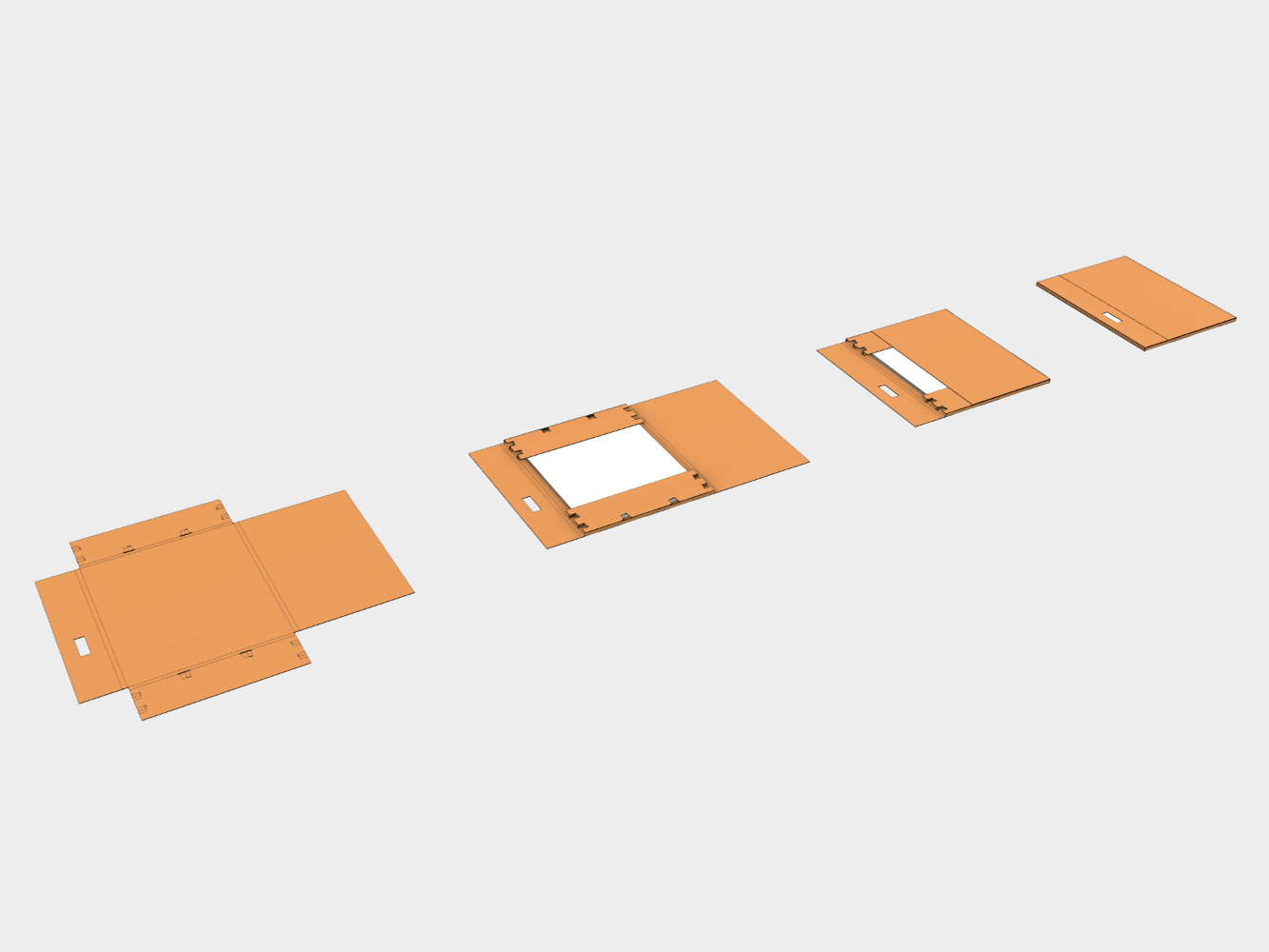

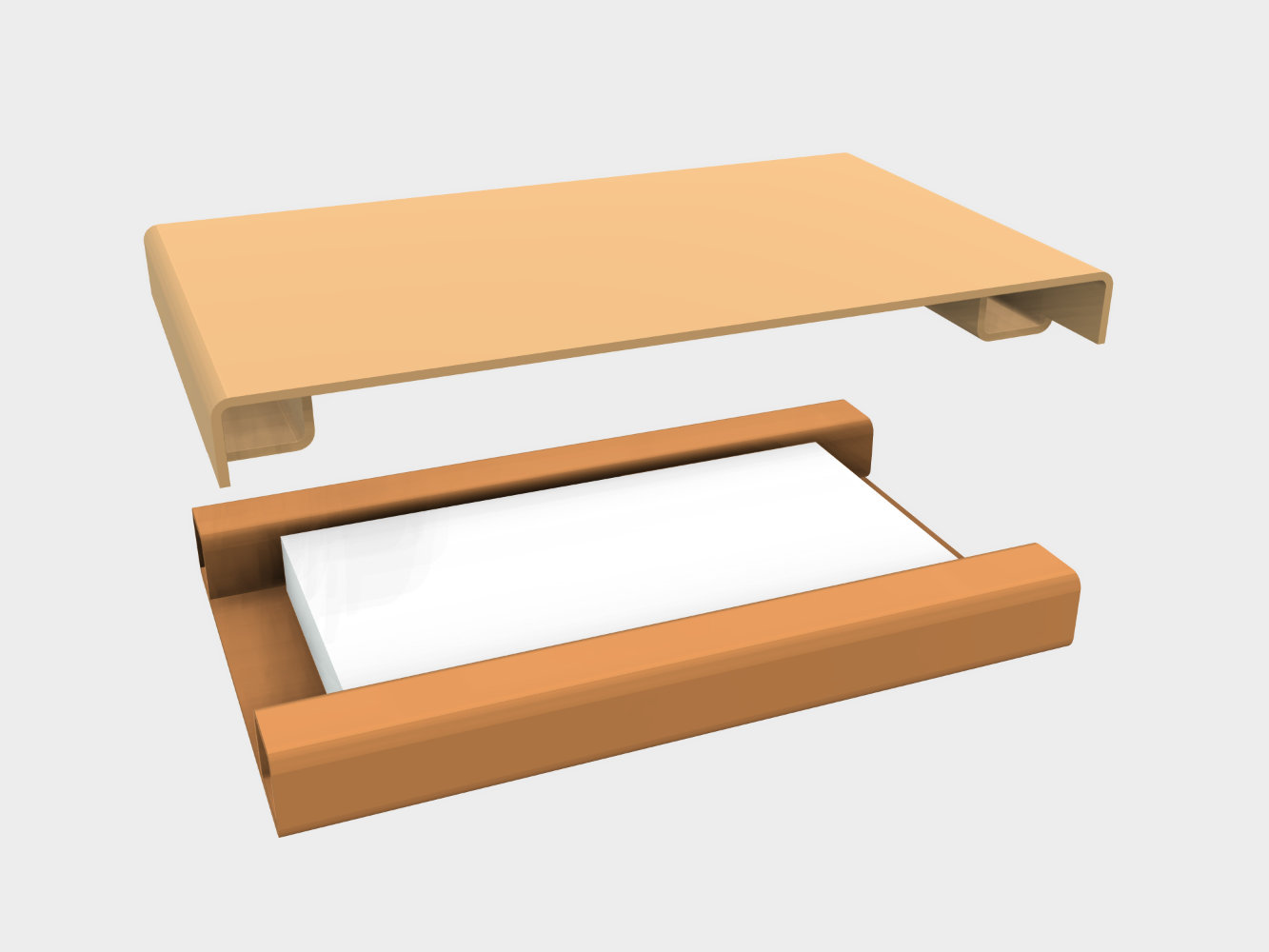

The focus of this concept is on a fully automated packaging process for products of batch size 1. The data of the individually incoming sheets are read by process control systems, barcodes, etc. and forwarded to a board cutting machine. On the basis of this data, two blanks (bottom and lid) are produced individually from endless cardboard, perforated at corresponding points, punched and then erected fully automatically. The 4-sided edge protection is ensured by bumpers which are erected during the fully automated folding process. The products are placed on the bottom of the cardboard, the lid is put on and the package is sealed. The applied tear thread allows easy, manual opening of the sealed package.

Your Advantages

- Individual cardboard blanks, 2-parts (bottom and lid)

- Elimination of plastic packaging and other packaging materials

- Optimization of logistics costs

- Optimal for products such as:

- Furniture parts

- Doors

- Flat parts

- Filling of product into cardboards is gentle through Pick & Place systems

- Interfaces to your process control system and remote maintenance

| Length | 300 - 2500 |

| Width | 300 - 2500 |

| Hight | 10 - 40 |

Metrics in mm

Further Advantages

- Compact and modular design that allows continuously format expansion within a specific size range

- Fast format changes through efficient adjustment systems

- Quick change, preset format modules

- Integration into fully automatic packaging lines possible

- Electronic parameter and recipe management

- Touch panel for easy and convenient operation with a detailed and self explanatory user interface for easy monitoring and troubleshooting support

- Automatic queries for cardboard stock and glue level

| Hot melt | for a quick and resistant gluing |

| Bond adhesive | for applicable folding cartons, Amarican cases, cardboard sleeves, etc. |

| Labeling, Coding | for identification and tracking |

| Camera Systems | for inspection and position detection |

| Process Control Systems | for evaluation, analysis and optimization of the entire packaging process - Shopfloor Management |

| Discharging | for the removal of damaged products |

| Leaflet inserter | for inserting brochures, instruction manuals, flyers, etc. |

| Sorting | for mixing different varieties of your product in one outer packaging |

| Distributor | to distribute products from one to multiple tracks |

| Separation | for separation of adjacent products and supply of downstream production processes |

loupe

loupe

loupe

loupe

loupe

loupe

loupe

loupe

loupe

loupe

loupe

loupe