We are passing through a very challenging time due to the consequences of the coronavirus. And we recognize that providing people ...

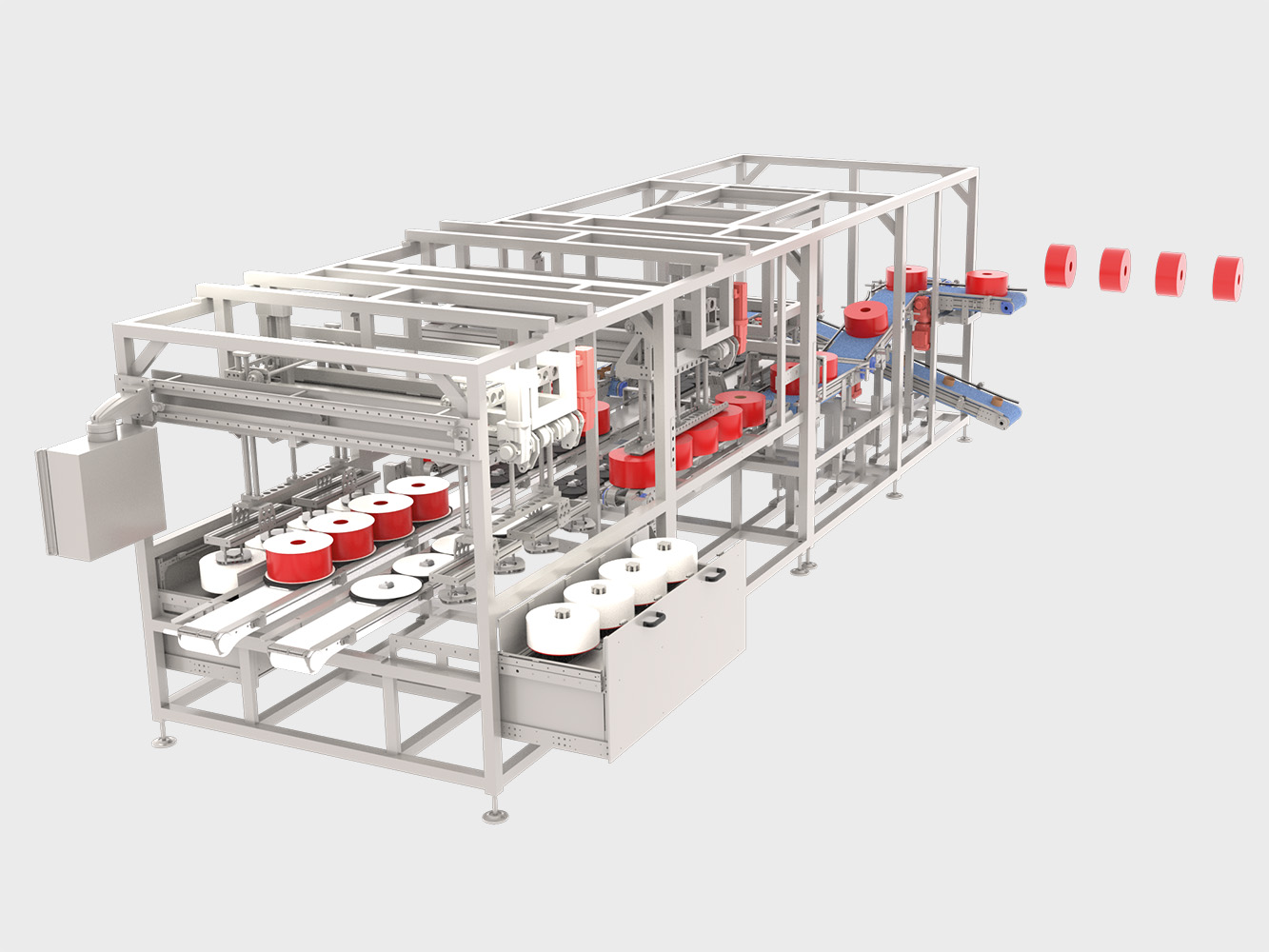

Read moreAUTOMATED PACKAGING LINE

With this system, rolls of adhesive tape are packed automatically into pre-cut cardboard blanks. The rolls can be provided with labels and a print in the inner core. Additional processes such as packing the individual rolls in a single bag or shrink-wrapping in film, can be integrated into the packaging line. A smooth process is ensured by using silicone release papers or silicone rings on the adhesive surfaces. Infinitely variable adjustment units and transport on carriers, enable the process of a wide variety of adhesive tape roll formats.

Your Advantages

- Output range: maximum 72 rolls/min.

- Continuous expansion of formats through efficient adjustment systems

- Transport of rolls with workpiece carriers, inner core printing and labelling

- Packaging options: bagged or shrink-wrapped

- Packaging: carton erection, roll grouping, insertion of intermediate layers into the carton

- Carton filling by robot

- Carton sealing with adhesive tape or hot glue, insertion of data sheet and carton label

| Hot melt | for a quick and resistant gluing |

| Folding and carding without adhesive | for optional manual straightening of the box |

| Bond adhesive | for applicable folding cartons, Amarican cases, cardboard sleeves, etc. |

| Labeling, Coding | for identification and tracking |

| Camera Systems | for inspection and position detection |

| Process Control Systems | for evaluation, analysis and optimization of the entire packaging process - Shopfloor Management |

| Discharging | for the removal of damaged products |

| Leaflet inserter | for inserting brochures, instruction manuals, flyers, etc. |

| Sorting | for mixing different varieties of your product in one outer packaging |

| Distributor | to distribute products from one to multiple tracks |

loupe

loupe

loupe

loupe