We are passing through a very challenging time due to the consequences of the coronavirus. And we recognize that providing people ...

Read moreOur team is looking back on a successful and highly visited LIGNA 2019, where we presented our innovations and highlights regarding "Sustainability through automated and scalable packaging solutions".

For us, face-to-face contact is the basis for good cooperation. We were very pleased to have many interesting conversations with our customers as well as to make many new contacts. Our exhibition highlights "integrated product protection" and the "clamp turner" generated a lot of interest. The exchange of information during these days was very informative and enriching for us as well as for our visitors.

We are already in the exciting phase in which we are expanding our concepts and innovations with the help of the knowledge gained from the conversations we had.

Thank you very much for your interest in our exhibition highlights and packaging solutions and for your confidence!

Sustainability by automated and scalable packaging solutions

With the new packaging ordinance, to replace polystyrene and foil with cardboard, the requirements for product packaging have increased. Sustainable packaging solutions and environmentally conscious technologies are in demand. Therefore packaging solutions with high product protection are required, which meet high quality requirements.

At LIGNA, we presented a matching concept: cardboard blanks are formed in an automated folding process, so that integrated product protection is created on the sides. In concrete terms, packaging means that no additional packaging materials are required to protect the product from all sides. Thus, a drastic reduction of the ecological backpack of these products is achieved while promoting a sustainable and efficient production.

Suitable for this, we have developed a packaging solution for the furniture industry in which individual parts are packed - for lot size 1 as well as for series production. One of the advantages of this concept is the scalability of the fully automated packaging system. The modular design enables both a minimum and a maximum solution as well as all stages of development in between: from the individual conveyor belt to the fully automatic packaging line. The customer has with WÄCHTER a contact in the entire packaging process.

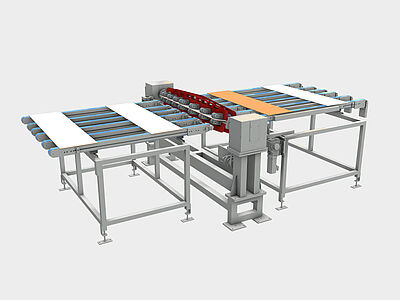

Turner for flat products

At our booth, we also presented our turner, which is intended for turning flat products. These packed products run through the turner and can be turned in various ways. For example turning of:

- every product

- every second product

- a product from the top

The turning requirements can be set directly by the control panel. As a result, the turner guarantees a high degree of flexibility with simultaneous high-speed production. The turner has proven itself especially in packaging processes, in the area of floor coverings and is a frequently used component in front of our packer.

Palletizing with collaborative robot technology

Convince yourself of the latest robot technology in the field of palletizing. Packed shelves are taken directly from a conveyor belt by means of collaborative robots and stacked on pallets.

The use of the collaborated robot systems brings many advantages, including:

- maximum flexibility in production with short changeover times

- elimination of a large protective housing

- risk reduction of injuries

- offer manufacturers the possibility of easy automation, to increase their competitiveness

We would be pleased, to advise you on a suitable concept for your palletizing and the topic of collaborative robot technology.